Machine Vision for Electronic Devices

The AI Vision System for Inspecting Electronic Devices

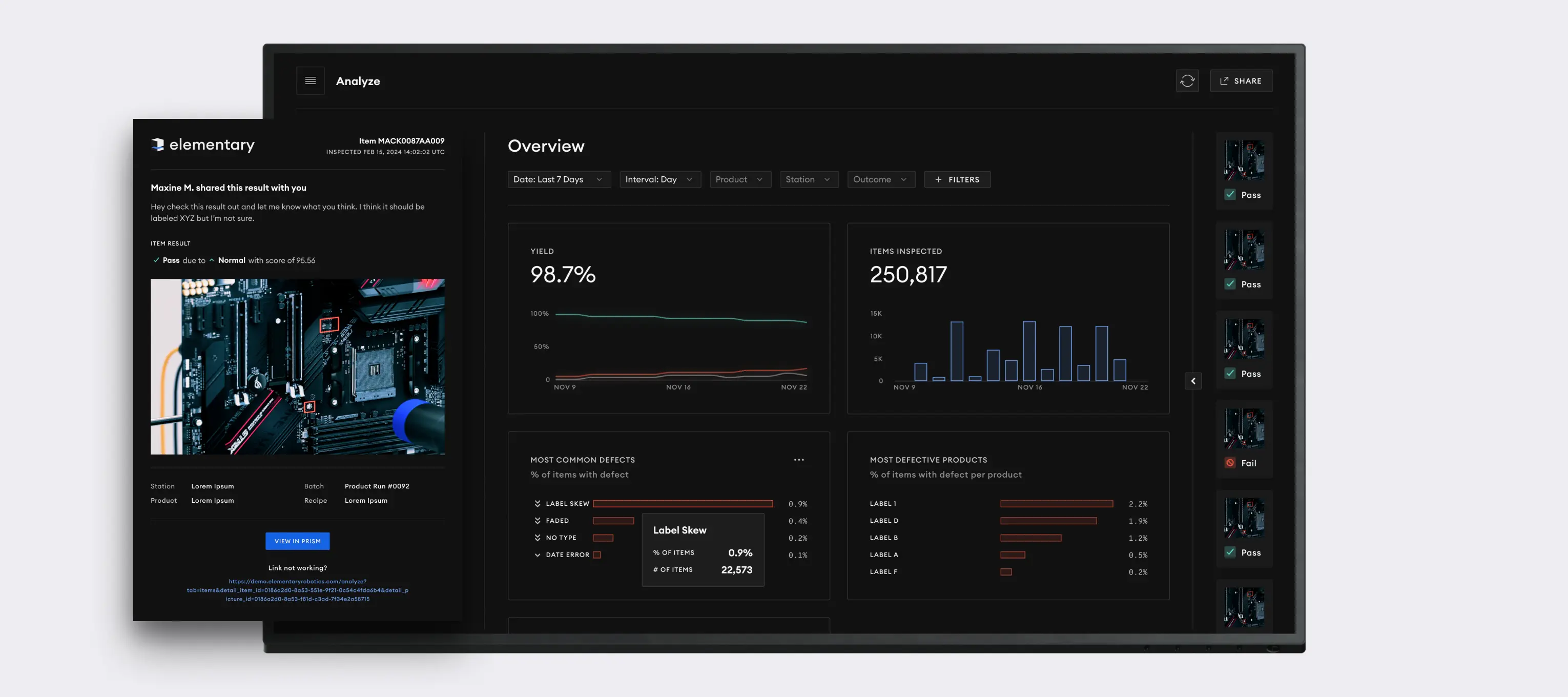

Automated inspection that prevents assembly defects, ensures compliance, and improves device reliability

INDUSTRY OVERVIEW

Electronic devices in automotive, aerospace, and consumer products are built from hundreds of components that must be perfectly assembled. Even tiny errors—misoriented connectors, missing fuses, or defective solder joints—can result in costly failures or recalls.

Key

Applications

Improve manufacturing quality with AI machine vision that inspects intricate components, welds, and assemblies, reducing defects and enhancing electronic components quality.

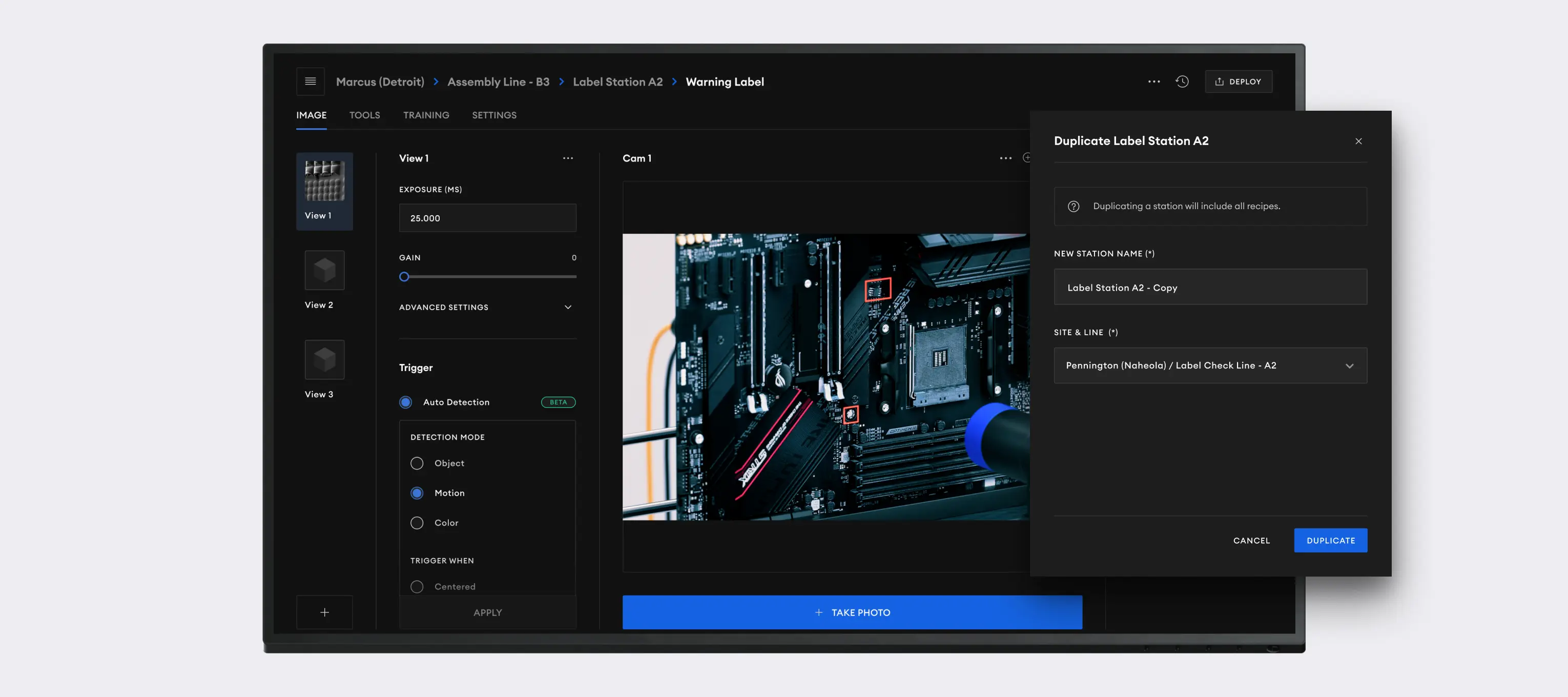

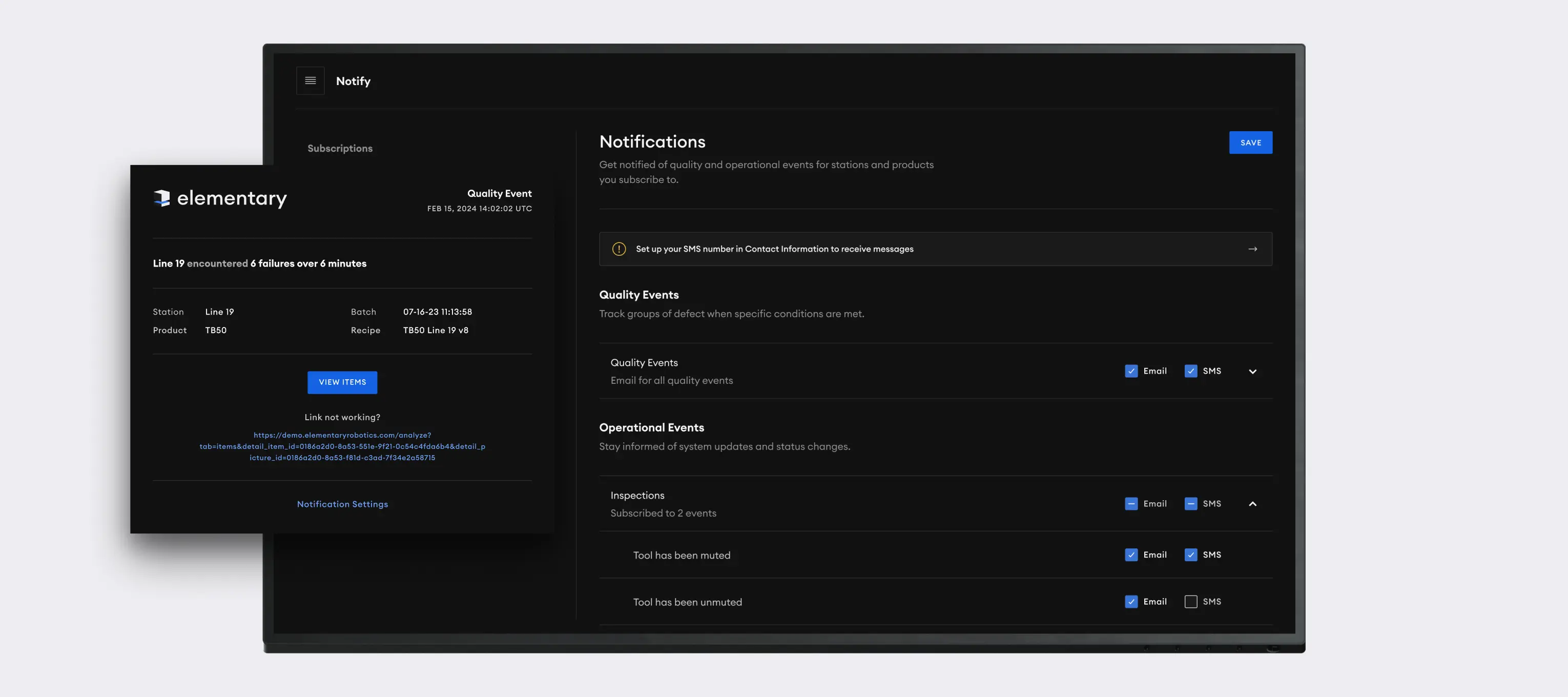

Key Features

and Benefits

Elementary's AI-driven vision sensors empower your production line and create tangible benefits for your business, from increased accuracy to significant cost savings.